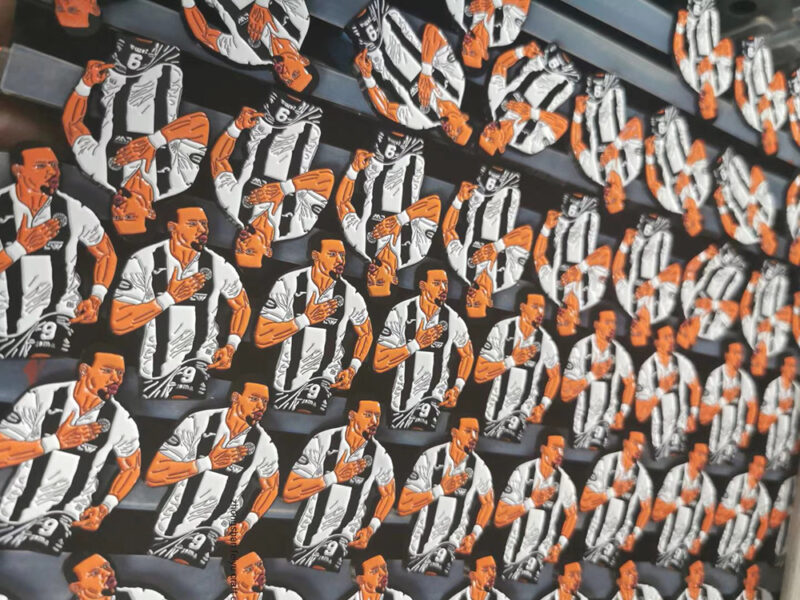

Metal Lapelpins belongs to a kind of badge (medal), generally mainly made by stamping, die-casting, biting plate process, the surface of the badge can be electroplated gold, antique gold, antique silver, nickel and other plating effects. It has the characteristics of simple and smooth lines and concave and convex patterns can be baked, enamel, printing and other surface color process to make the product in a wide variety. Gold and silver badges are the most expensive, followed by copper badges, zinc alloy badges, and iron badges are the cheapest.

Metal badge original embryo is used to make baked lacquer badge, soft enamel badge, drip lacquer badge, printing badge, embossed badge as the first step, metal badge after baking lacquer or soft enamel process and then processed into a beautiful badge with rich colors.

Metal badges have a strong sense of three-dimensionality and various patterns with outstanding hierarchy, which is one of the most used badge products among high-end user types. Not on the color metal badge made into convex and concave pattern production period will be shorter, suitable for large quantities of badge production.

Generally, badges production flow process is as followings.

Step 1: design badge or lapel pin draft. With the popularity of computer technology, the computer drawing replaces the previous manual drawing. Badge artwork design commonly used production software, Adobe Illustrator If you want to generate 3D badge effects, and need the support of software such as 3D Max. About the color system, usually use PANTONE SOLID COATED, because PANTONE color system can better match the color, reduce the possibility of color difference.

Step 2: Make the badge or lapel pin mold. Import the draft designed in the computer into the fine engraving machine program to compile the knife path for mold carving, in the carving process to pay attention to the knife pattern coarse and fine, carved after the figure to engage in a comparison of the mold whether there are missing. Finally, the mold should be heat-treated to strengthen the hardness and durability of the mold.

Step 3: Pressing. Install the heat-treated die on the press table, and turn the pattern pressed on different badge-making materials such as copper or iron sheets.

Step 4: Punching. Use the pre-made die to punch down the product according to its shape with the punching machine.

Step 5: Polishing. Put the products punched down by the knife mold into the polishing machine to polish, remove the burrs of stamping and improve the finish of the products.

Step 6: Solder the accessories of the badge or lapel pin. Put the back of the product with solder and solder the standard accessories of the badge or the accessories requested by the customer.

Step 7: Plating and coloring. Plating the badge or lapel pin according to the customer’s requirements, can be gold plating, silver plating, nickel plating, red copper plating, etc., and then coloring the badge according to the customer’s requirements. After coloring, high temperature baking is carried out to strengthen the color fastness. Through this step, a complete badge that meets the requirements of the guests is made.

Step 8: The finished badge or lapel pin is packed according to the customer’s requirements. The packaging is generally divided into ordinary packaging and high-grade packaging such as brocade boxes, etc., for which we generally operate in accordance with the requirements of customers.